3D printing is a type of additive manufacturing that creates a solid object from a digital model. It is often used for rapid Prototyping and the creation of lightweight geometric objects.

In the aerospace industry, 3D printing is used for various things, such as engine and turbine parts. It is also used to create customized parts for individual users. Contact By3Design now!

As the name implies, Rapid Prototyping with 3D printing is a way to create a physical prototype of an idea quickly and efficiently. It is a key step in the design process that allows designers to see their ideas as they would actually be built and test them before investing in full production. This saves time and money by reducing the number of design iterations needed, and it reduces the risk of costly mistakes during manufacturing.

There are several different ways to create a rapid prototype, but the most common method is by using a 3D printer. This technology can reduce the time it takes to produce a prototype from a digital design file by several weeks or months, which allows designers to make quick and easy changes before moving forward with production. The ability to rapidly change designs also helps improve product quality by ensuring that the final product meets user needs and expectations.

The first step in the rapid prototyping process is to create a digital model of the desired product using computer-aided design (CAD) software. This process is critical, as it ensures that the model accurately represents the intended design and enables it to be tested against real-world conditions. It also enables the designer to identify any areas for improvement and iteration.

Once the digital model is complete, it is transferred to a 3D printer, which builds up layers of material until the finished product is created. The materials used in a 3D printer vary by machine and application, but they can include polymers, composites, and even industrial metals. The choice of material depends on the application, so it is important to choose one that offers the right strength and durability for the job.

Once the prototype is completed, it is subjected to rigorous testing and evaluation to determine if it can meet the desired performance standards. This testing can include simulated stress tests, real-world user feedback, and a variety of other factors that can help identify any areas for improvement or potential issues. This information is then used to create a new iteration of the prototype, which is retested until the desired performance is achieved.

Customizable Products

In addition to being a time-efficient process, 3D printing enables manufacturers to produce customized products at scale. This feature is a great advantage for brands that are looking to distinguish themselves from their competition, while fostering a stronger emotional connection with consumers. In addition, customized products can reduce waste by eliminating unnecessary production of duplicate items.

To print a customized object, designers first create a virtual model of the desired product using computer-aided design software. The virtual model works like a blueprint that the printer can “read.” Once the design is ready, it is “sliced” into layers by the printer, allowing for the creation of different parts of the object. The printer then bonds each layer of the material with the previous one to form a solid object.

The versatility of the printing process allows for a wide range of materials to be used. Some of the most common materials include plastic, metal, and ceramics. Additionally, the 3D printing process can be used to make objects in a variety of colors and finishes. The technology is especially useful for creating intricate models and prototypes, which can be difficult to replicate with traditional manufacturing methods.

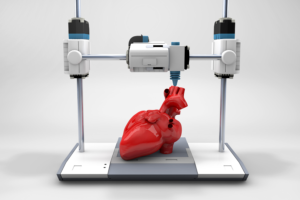

While 3D printing can be used to produce a variety of different types of products, it is particularly well suited for creating medical devices. In fact, the process has already been used to manufacture medical implants and dental models. In the future, this technology may be used to create more complex medical devices, including surgical instruments and body organs.

Moreover, 3D printing can also be used to produce spare and replacement parts for existing products. This can significantly reduce costs and improve the efficiency of organizations’ operations. In some cases, companies may even choose to operate on a ‘take one, make one’ policy, wherein a small number of spare parts are printed on demand, thereby avoiding the need for storage or warehousing.

Although 3D printing is an innovative new technology, it is not without its limitations. Some of the most important limitations are related to the quality of prints and the accuracy of the printing process. However, continuous improvements in both the printing technology and the quality of materials are addressing these issues.

Cost-Effective

The initial investment for a 3D printer can seem expensive, but the technology quickly pays for itself in the long run. By printing parts directly from CAD files, it cuts out the costs of models, tooling and prototypes. With traditional manufacturing, these steps add up and can significantly increase cost.

Creating a 3D model requires computer-aided design (CAD) software, which creates a blueprint that the printer reads and follows to build up the object layer by layer. Depending on the technology used, this can be as simple as building on the XY plane or as complex as slicing into hundreds or even thousands of thin layers. Choosing the right layer height and orientation can also dramatically reduce material costs by decreasing the need for support structures, which must be added to keep the printed part from falling apart during printing.

Another way 3D printing can lower production costs is by eliminating the need for tools, reducing machine downtime and cutting back on labor. 3D printing allows manufacturers to work on a larger scale, so they can produce more parts in less time with less overhead. This makes it possible for businesses to test new products on the market faster and more inexpensively.

In addition, many of the materials used in 3D printing are much cheaper than those in traditional manufacturing processes. Choosing the right type of filament or resin is critical, though. Stratasys Direct has a variety of resources, calculators and tools that can help determine the most affordable options.

Other factors that elevate the cost of printing include print failures, which can squander materials and time. An unsuccessful print eats up not only the PLA, ABS or resin being used, but it also wastes electricity and machine time that could have been allocated to successful prints. By improving print quality, utilizing software to optimize designs and infill patterns, and performing regular maintenance on the 3D printer, companies can make significant savings.

In addition, some 3D printing technologies can save money by allowing the creation of lighter parts. This is particularly useful in industries that must meet weight to speed ratios, like motorsport and aerospace. In these cases, saving an ounce or two is a big deal. 3D printing is one of the best methods for achieving this without compromising strength or structural integrity.

Environmentally Friendly

3D printing is not only fast, cost-effective, and customizable; it’s also environmentally friendly. The technology eliminates the need to transport raw materials or finished products across long distances, which are often energy intensive and produce a high rate of carbon emissions. In addition, it eliminates the need to store products in warehouses or shipping terminals, which reduces space and energy requirements.

The 3D printing process itself produces fewer emissions than traditional manufacturing techniques, although the type of material used can impact the environmental footprint. For example, ABS plastic, a common 3D printing filament, releases volatile organic compounds (VOCs) during the printing process. However, the technology has been developed to limit and eliminate VOC emissions by incorporating ventilation systems and filtration in the printers.

Another environmental benefit of 3D printing is that it eliminates the need to create large quantities of identical products, which can waste materials and lead to excess inventory. 3D printing allows companies to create a wide range of products, which are customized to individual needs and tastes. This also allows for the creation of replacement parts, which can extend the lifespan of existing products and further reduce waste and energy consumption.

In addition, many types of plastics used in 3D printing are considered eco-friendly, and some printers can use recycled or reused materials to cut down on waste. The choice of printer and print setting can also influence the environmental impact, as well as choosing nontoxic materials that will not react with the environment.

Lastly, the ability to produce products on-site can further lower energy and environmental costs by reducing transportation costs. For instance, Vestas, the world’s leading wind power company, uses Markforged’s Digital Forge additive manufacturing platform to help streamline its production processes and free up space in its facilities.

While the sustainability benefits of 3D printing are clear, it is important to note that the technology is still in its early stages. Research has shown that to produce the same weight of object, 3D printing requires 50 to 100 times more electrical energy than injection molding machines. In the future, this may change as the technology continues to develop and as it becomes more efficient.